Eco Electric Series – Eco Electric DC Conveyor

Home » Product Areas » FA Equipment Sold Separately » Eco Electric Series – Eco Electric DC Conveyor

Eco Electric Series – Eco Electric DC Conveyor

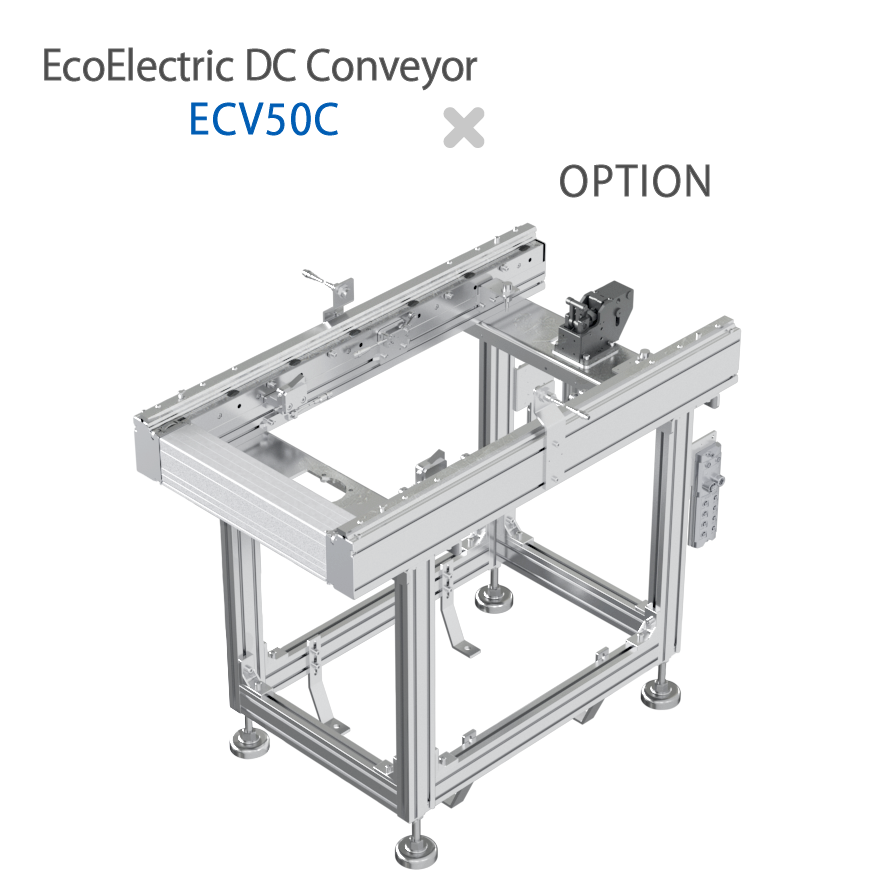

Eco Electric DC Conveyor [ECV]

An eco-electric DC conveyor that combines the strength to carry heavy objects of up to 280 kg with the safety of being able to easily stop the transfer with one hand. There is no need for safety fences or sensors that detect the intrusion of people, which must be installed to ensure human safety, and “collaboration” work with machines is possible.

It has a good reputation for production lines in the automobile industry, such as applications where people assemble parts while flowing products on a conveyor.

By combining with the eco-electric series, a production line that does not require air equipment can be realized, and running costs can be significantly reduced.

* Since the eco-electric AC conveyor is AC driven, it is necessary to install a drive panel, but in the case of the eco-electric DC conveyor, the drive panel is not required because it is only connected to 24V DC by the I / O slave.

Features

Scalability / Flexible

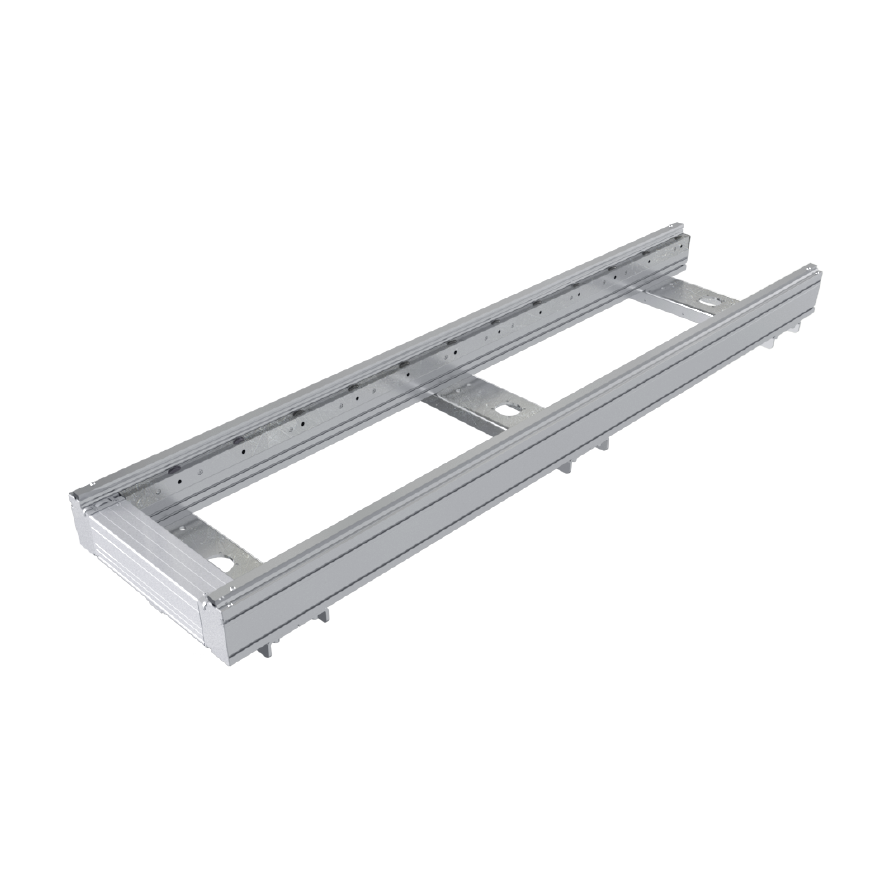

Modular conveyor allows immediate use after installation.

Flexible response to layout changes, etc.

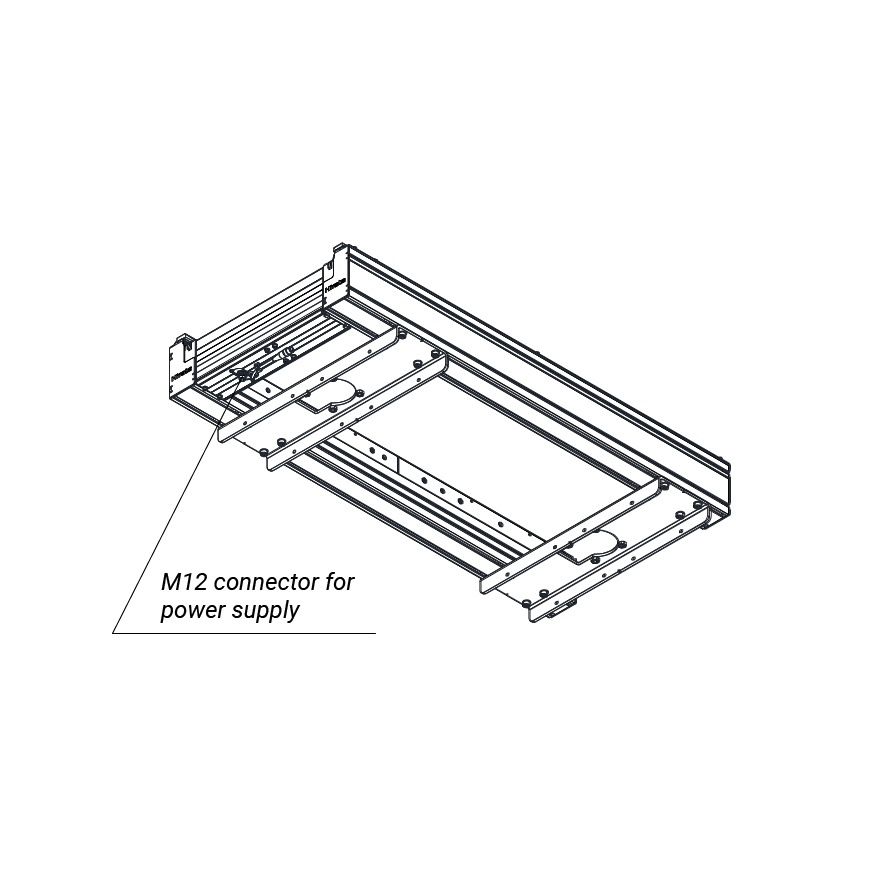

Easy wiring with only M12 connector connection, so instrumentation work is easy.

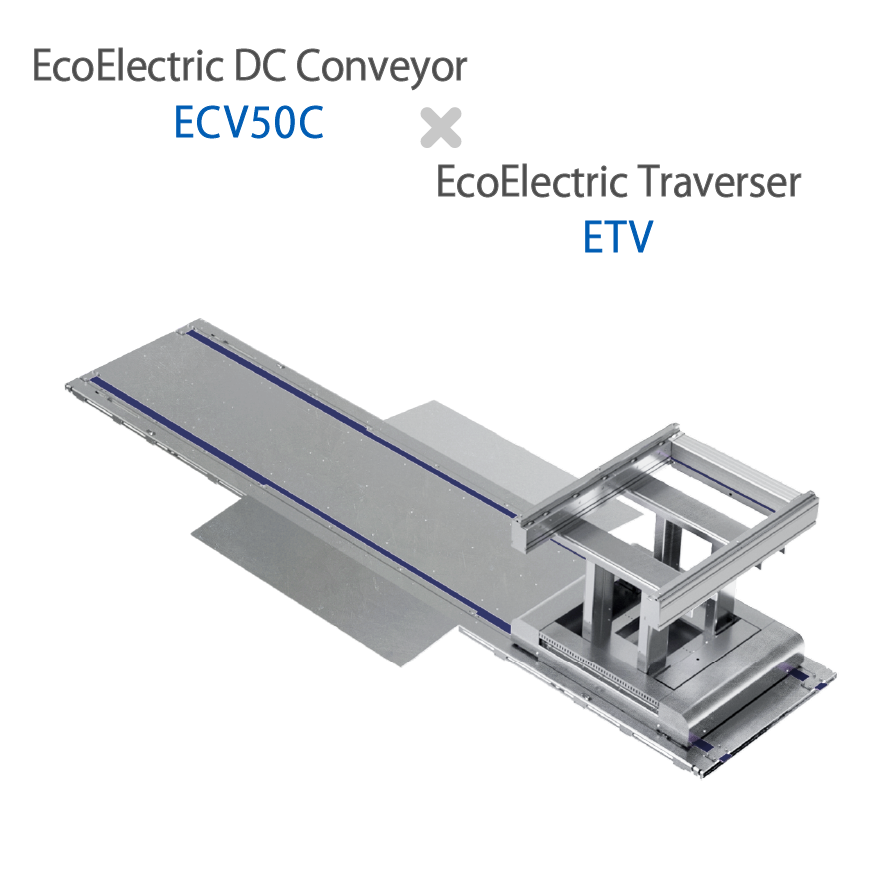

Since there is a large space in the center of the conveyor, it is easy to expand the positioning device, etc.

Slits are prepared in advance on the side of the frame, and parts can be easily attached by fixing with bolts.

Maintainability

Unique structure eliminates the need for chain adjustment [patented].

Easy replacement of roller unit and motor.

Since the drive chain is inside the frame, it is structurally difficult for oil and dust, which are often generated at production sites, to enter.

Energy saving / low cost

By combining with our original eco-electric series, it is possible to realize an air equipment-less transfer system with a small number of peripheral parts and low running costs.

Initial cost can be reduced because expensive power panel is not required.

Since it is DC24V, it consumes less power than AC200V and can reduce running costs.

Safety

The drive chain is not exposed and is safe.

Space Saving

Since the motor position and drive transmission counter shaft are installed at almost the same position as the transport roller, the conveyor cross section is extremely compact and a low floor is realized. Can be transported at a low position.

Since the motor is installed inside, there is no need to worry about the position and orientation of the motor.